- Concrete Batching Plants

- Concrete Mixing Plants

- Mobile Concrete Batching Plants

- Compact Concrete Batching Plants

- Stationary Concrete Batching Plants

- Cement Silos

- Cement Feeding Systems

- Concrete Pumps

- Concrete Recycling Systems

- Containerized Concrete Batching Plants

- Concrete Mixers

ELKON Concrete Batching Plants

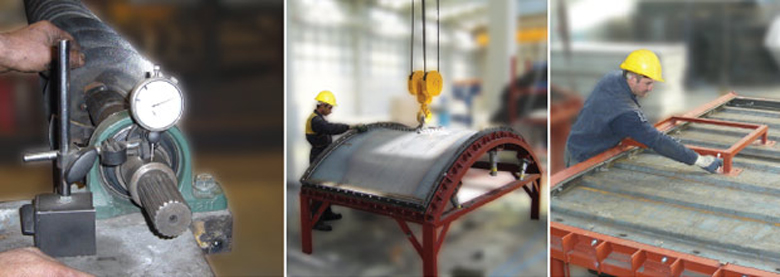

ELKON MANUFACTURING TECHNOLOGIES

It is not easy at all for the customer to choose the most appropriate supplier among many of them. Because concrete batching plants are investment products and it is necessary to be very careful in this subject. Choosing the wrong supplier causes irremeable consequences. So that there is need to make the decisions according to evaluation of the parameters like experience, technical sources, skills, manufacturing technologies, components and engineering solutions.

COMPUTER AIDED DESIGN

ELKON, who has wide R&D and project design departments, uses CAD programmes in all his designs. Through this way, error rate is decreased to zero and millimetric accuracy is reached in manufacturing. Simulation, static and dynamic analysis of new designed products can be actualized by these programmes. Also, accurate components are produced by special machineries using CAM.

MATERIAL PREPARATION

Human factor has a great effect on final product. Because concrete batching plant manufacturing is an effort based sector. Minimizing this effect means making the process indepented from human effect as much as it's possible and standardizing the parts. Laser technology is applied to cut and to pierce the parts which will be used in manufacturing process. Thus it's possibile to get sensivity. After this process, chemical surface cleaning operation is applied to these parts they will be ready to be used in manufacturing process.

MANUFACTURING AND CONTROL PROCESSES

As we mentioned before, human factor has an effect on final product. This issue is also valid for equipment preparation and manufacturing processes. Elkon succeded not only isolating the manufacturing process from human factor but also to reach high sensitivity in the production with the special moulds and tools that he designed. For instance the mixers, the panels of aggregate silos, cement silos, manufacturing of the metal construction of winterized covering. Moreover Elkon mostly prefers bolted type connections in his production. Bolted type connections is not only proof of the sensitive production but also provide resistent structure which can be easily interfered. Also there will be no defection in the materials on the connection points as it's in the welding technic. In addition to this It provides great advantage to the customer during the transportation. (It's possible to make more reliable and cheaper packaging)

PAINTING AND GALVANIZATION

Parts manufactured in special moulds and tools, are being galvanized and painted to have protection against corrosion. Processes which are seen as optional in Europe, are presented to customer as standard by ELKON. For example water weight batchers, additive wieght batchers, walking platforms, maintenance gates, paraphets, stairs and conveyor chassises are galvanized as a standard. Also ELKON uses JUTON brand epoxy primers and top coatings which have great resistance against corrosion. Dyeing process is being done in modern painting cabins. Each ELKON factories have two painting cabins.

COMPONENTS

ELKON goes on his technological, quality and reliable concrete batching plant manufacturing principle thereby using 2 parallel ways: High manufacturing culture and Choosing reliable, quality and proper components. Component selection requires serious experience and feedbacks. At the same time it is an optimization problem. For example if you manufacture a conveyor which will transfer a certain capacity sand, you should solve these problems: selecting the correct drum and roller, appropriate conveyor angle, type of conveyor, conveyor belt wideness and drive system.

THE FIRST AND THE BIGGEST MOBILE CONCRETE BATCHING PLANT MANUFACTURER IN TURKEY

The studies for creating more economic or technological solutions for the increasing demands of human beings, are variable and increasing. This situation is not different for construction equipment manufacturing in construction sector. ELKON who has been manufacturing construction machineries (concrete batching plants) and presenting important technological solutions to the sector since 1975. Definitely, one of these solutions is Mobile Concrete Batching Plants. Mobile Concrete Batching Plantproject in 1999. With his great experience and technological background, R&D, project and prototype studies were completed in 2000. In 2001, Elkon manufactured ELKON MOBILE MASTER-100 Fully Automatic Mobile Concrete Batching Plant which is the first mobile concrete batching plant in Turkey and exported it to Mezamet, France. These studies were improved and Elkon started manufacturing of another model ELKON MOBILE MASTER-60 Mobile Concrete Batching Plant in 2002.

CONFORMITY WITH STANDARDS

Increasing numbers of concrete batching plant manufacturers creates competition. Manufacturers who is in cost-based mentality, want to reduce the cost thereby ignoring standards during the production. In other words, a designer has to consider safety of workmen, maintenance and repair easiness. For example, mixer gates should be equipped with safety switches; cement, water and additive weight batchers should be reached by stairs and should be equipped with platforms and paraphets. Unfortunately, ignoring these standards to reduce the cost is becoming widespread among European manufacturers. All regulations which required by CE and GOST-R standards are being applied to ELKON concrete batching plants carefully.

COMPLETENESS

If an investor hasn't invested in concrete batching plant sector before, he may not have enough knowledge about this subject. This situation is being abused by many manufacturers. During the commercial offer preparation period, manufacturer convinces the customer that customer can produce many parts of the plant by himself to reduce the cost. But for example, production of upper panels of aggregate silo, cement silos, supporting structures by customer is a completely wrong application. Because it would be the first time for the customer and it would be very difficult to produce the items at reasonable costs, on time, with required quality and guarantee. However ELKON directs his customers, shows possible alternatives and helps about the scope of business. Furthermore ELKON carries out analysis for his customers for free.

CONCRETE BATCHING PLANTS PICTURES

Mobile Concrete Batching Plants Compact Concrete Batching Plants Stationary Concrete Batching Plants